Products

CODERE SA offers a complete range of heat treatment solutions, including semi/fully automatic or manual door-type furnaces, quenching automation systems, belt transfer furnaces, and pushing furnaces. Our modular and specialized equipment ensures optimal results for various types of metals and alloys. Contact us for more information.

BELL FURNACE SEMI/FULL AUTOMATIC OR MANUAL - SYSTEM 250

A modular heat treatment line featuring a door-type furnace operated under a protective atmosphere with functional separation of stations and direct quenching transfer:

Transfer of the load from the furnace to the quench tank is achieved by a simple sliding action, without a hooking mechanism.

Furnace-to-tank transfer time is under 15 seconds.

Integration of all types of cooling fluids, providing a wide variety of furnace/tank combinations.

Easy expansion of the line to meet new requirements (in terms of capacity and treatments – continuous development).

Particularly suited for producing parts in medium and small series that require diverse heat treatments, especially for delicate components sensitive to deformation.

Quenching transfer is performed under atmosphere without any temperature loss before immersion.

Operating Modes:

Manual: The System 250 line can be configured in manual mode, where an operator handles the load module by module using dedicated electrical equipment (see attached image).

Automatic: In automatic mode, a robotic manipulator carries out the entire process autonomously, thanks to our production control software HT View. A complete explanation of the system is available in the video below.

HARDENING AUTOMATE - SYSTEM 280

A door-type furnace equipped with a metallic retort and an integrated water quench tank for treatments under a protective atmosphere:

Parts are placed in baskets.

Rapid atmosphere conditioning and preheating allow for a machine-tool-like start/stop mode.

Suitable for treating copper-based alloys, gold, platinum, aluminum, and titanium.

Transfer from the heating chamber to the quench tank is performed under gaseous protection, preventing oxidation and ensuring no temperature drop.

Compact installation with a small footprint.

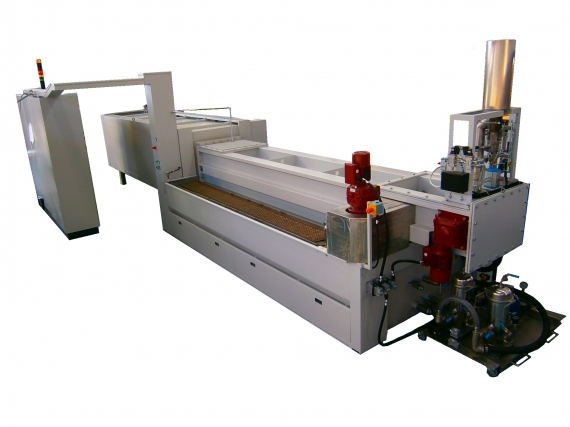

CONVEYOR BELT FURNACE - TYPE 300

A through-type furnace featuring a horizontal metallic retort and a transport belt:

Passage time is adjustable via a frequency converter.

Heating and cooling of parts are performed under a gaseous atmosphere, ensuring excellent treatment uniformity.

Rapid atmosphere conditioning and preheating.

Specifically designed for treating stainless steel, copper-based alloys, and gold.

PUSHER FURNACE - SYSTEM 340

A furnace equipped with a horizontal metallic retort and an integrated water quench tank for treatments under a protective atmosphere:

Parts are transported in baskets.

Rapid atmosphere conditioning and preheating allow for a machine-tool-like start/stop mode.

Suitable for treating copper-based alloys, gold, aluminum, titanium, and platinum.

Transfer from the heating chamber to the quench tank is executed under gaseous protection to prevent oxidation without any drop in temperature.

Particularly suited for long profile parts.

>> Other products on demand

Feel free to contact us to obtain our brochures or for any other inquiries.